We Are Overachievers. We Go The Extra Mile to ensure complete quality control, from design to delivery.

Sawyer Fabrication maintains the highest levels of quality assurance at every stage of the manufacturing process. Our team includes a full-time quality control inspector who reviews everything we produce, ensuring uncompromised build quality and precision tolerances. This guarantees that everything we fabricate is built exactly to spec, with quality assurances to satisfy project requirements and certifications.

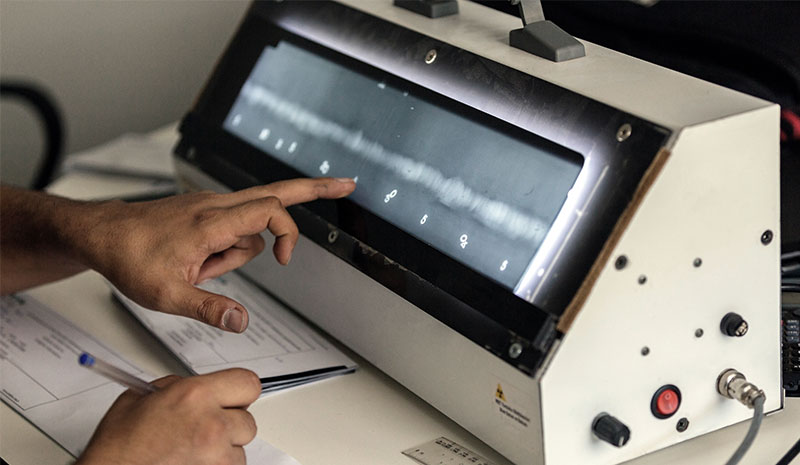

Our inspector is certified Level II by The American Society for Nondestructive Testing (ASNT) for:

- Liquid Penetrant Testing (PT)

- Magnetic Particle Testing (MT)

- Reading Radiographic Testing (RT)

WELDING Certifications

Our welders and fitters are meticulously tested, trained, and audited to guarantee conformance to project specifications and Sawyer Fabrication's expectations. From precision steel fabrication to industry-leading turnaround times and delivery schedules, our team is guaranteed to outperform your requirements.

Our comprehensive quality control process ensures that all stringent codes and regulations are exceeded during fabrication, as well as in post-production inspections.

We maintain active welding certifications for a multitude of qualified procedures and processes. Additionally, we are capable of writing and testing new Weld Procedure Specifications (WPS) in-house with no impact to your project deadline. With Sawyer Fabrication, you can rest assured that all code specifications will be met whether or not they are required for the project.

We control our welding and fabrication procedures in compliance with the American Society of Mechanical Engineers (ASME) and the National Board Inspection Code (NBIC) to meet the strictest global welding requirements.

Sawyer is certified with ASME R and U stamps. These certifications guarantee that we are capable of meeting ASME and NBIC standards for the fabrication, repair, and alteration of boilers, pressure vessels, and other pressure-retaining items.

We have welders actively qualified to weld in the following specifications and codes:

- AWS D1.1 Structural Steel Welding

- ASME Boiler and Pressure Code (BPVC) Sections I, IV, VIII X and/or XII

expert Inspection & certified Quality Control

Our meticulous inspection processes allow us to build a culture of quality assurance within everything we do. Precision fabrication demands unwavering quality control and accountability, ensuring flawless final products.

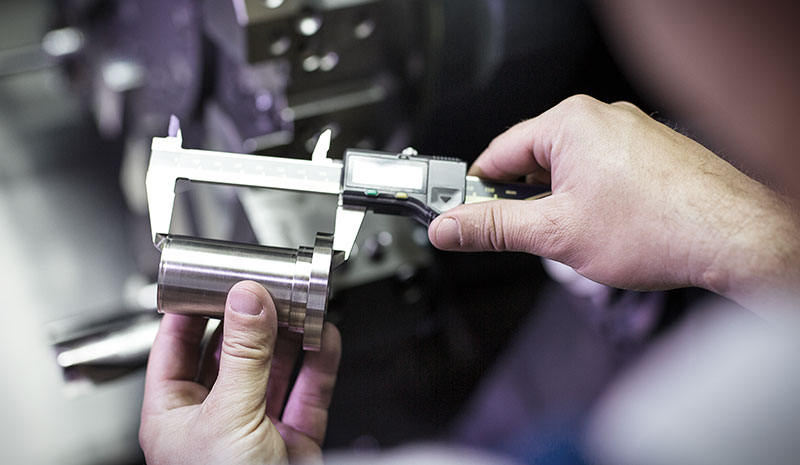

We achieve this through industry-leading quality control methods, rigorously evaluating each stage of the metal fabrication process, including:

- Receiving – Material specifications

- In Process – Dimensional specifications

- Final Inspection – Performed by our Quality Control Inspector and coordinated with required outside inspectors

Inspections are constantly performed to ensure every project meets:

- Authorized requirements

- Non-destructive examination

- Design and engineering drawings

- Documentation

- Material specifications

- Required standards and certifications

ISO 9001:2015 Certification

We are proud to be ISO 9001:2015 certified, demonstrating our adherence to international standards of quality management. This certification is a testament to our ongoing commitment to excellence and our ability to consistently meet customer and regulatory requirements.

- Consistent Quality: Ensuring that every product we deliver meets stringent quality requirements.

- Customer Satisfaction: Continuously improving our processes to meet and exceed customer expectations.

- Regulatory Compliance: Adhering to all applicable legal and regulatory standards.

- Risk Management: Proactively identifying and mitigating risks to enhance the reliability and efficiency of our operations.

- Process Improvement: Engaging in ongoing evaluation and refinement of our quality management processes to drive innovation and operational excellence.