Fearless Fabrication

We are bold. We are driven. We get it done.

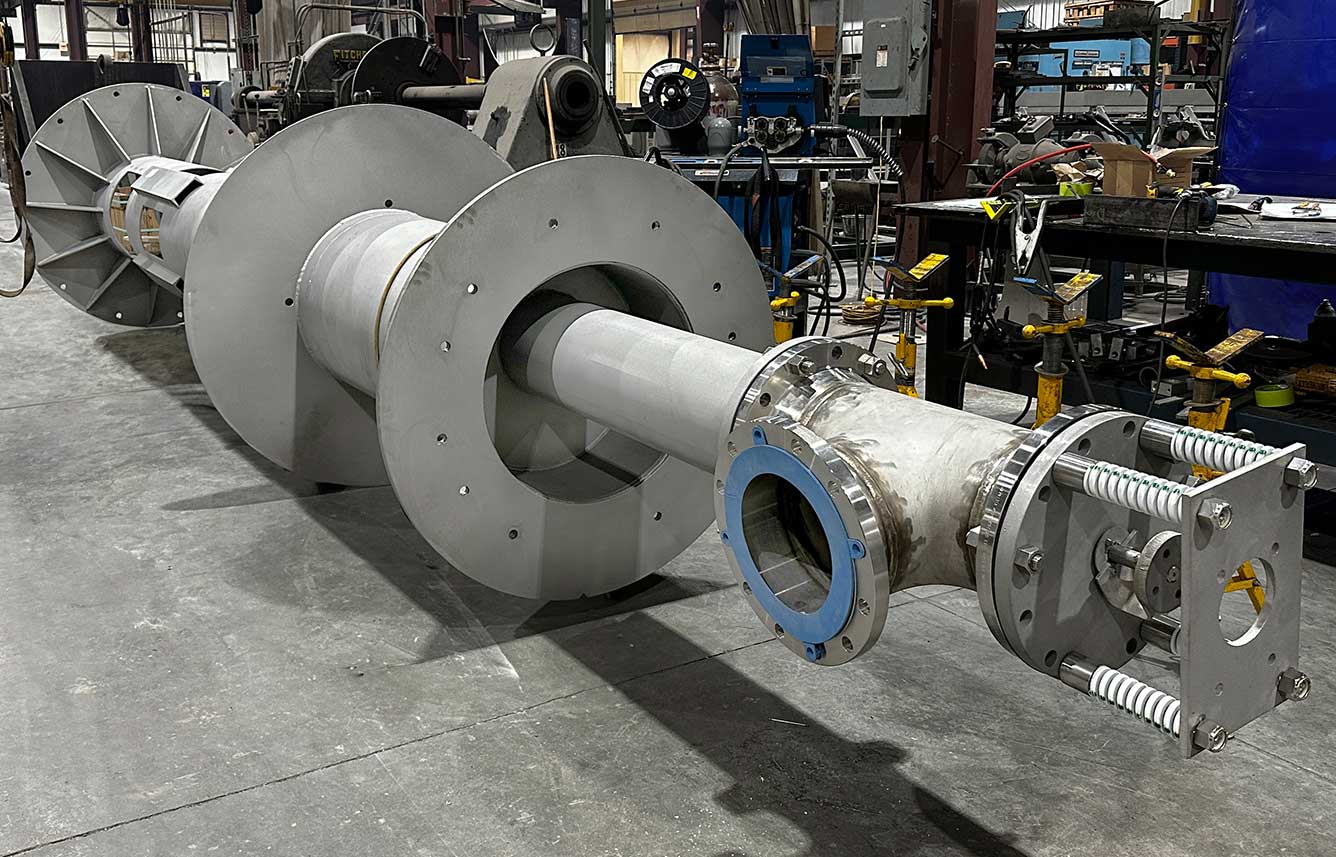

Every project is an opportunity to push our craft forward — sharpening our expertise in custom fabrication and machining. With extensive welding capabilities and unmatched skill in steel fabrication, our team delivers precision work that stands at the forefront of the industry.

If it can be fabricated our team can build it. No challenge is too complex, and no standard is too high.

At Sawyer Fab, We Are Masters of Our Trade — Bold in Our Approach, Taking on Every fabrication Challenge, and Delivering With Precision.

We thrive on challenging projects and tight deadlines, bringing unmatched expertise to every build.

For more than 77 years, we’ve taken manufacturing expertise to custom fabrication with quality you can see and craftsmanship you can trust. Our team blends creativity, precision, and a relentless commitment to getting the job done right — no matter the scope or complexity.

We love to build stuff. Our fabrication team is ready to take on any challenge and exceed expectations at every level.

Fabrication Excellence Backed by Proven Quality Control

Forward-thinking in our approach and relentless in our execution, we bring every project to life with precision, purpose, and pride. Our refined processes keep work moving efficiently while maintaining the highest standards at every stage — from the first cut to the final inspection.

Every build is backed by rigorous quality control, ensuring that nothing leaves our shop unless it meets our exacting standards.We combine skill, attention to detail, and an unwavering commitment to doing things right, making us the partner you can count on for exceptional custom steel fabrication.

Fabrication Without Compromise

We thrive on high-stakes builds and the pressure to perform. From initial planning to the final inspection, we bring precision, skill, and relentless commitment to getting the job done right.

Let’s create something that exceeds your standards.