Flexible solutions, shorter lead times & quality craftsmanship

Sawyer's welding and fabrication capabilities provide a wide range of precision from design to delivery.

We transform your ideas and designs into realities. Our welders, fitters, fabricators, machinists and technicians are calibrated to the highest skill level. Their diverse expertise and years of experience puts us a step above the competition.

Sawyer Fabrication's reputable metal fabrication shop is fully outfitted for Certified R&U stamped ASME Vessels, Piping Systems, Modular Process Skids, and Heavy Structural Weldments, along with Conventional and Custom Machining. With reliable manufacturing processes and world-class craftsman, there's no fabrication job that Sawyer can't tackle.

We don't shy away from engineering challenges - we thrive on them.

Shop Capabilities

- 85,000 sq. ft. facility includes blast and paint booth

- 35,000 sq. ft. heavy weld bay

- 40 acre property

- 10 acre lay-down yard

- 70 employees

- 7.5 ton bridge cranes (4)

- 20 ton bridge cranes (3)

- 1 ton jib cranes (6)

- Honing machine (1)

- ½ ton cranes in machining bays (4)

- Forklifts up to 55,000 lbs.

- Weld machines (22)

- Certified welders (20)

- CNC machines (9)

- CNC lathe machines (9)

- Lathe machines (5)

- Mill machines (4)

- Drill presses (3)

Welding & Fabrication Capabilities

- Welded Piping – for a variety of systems

- ASME R & U Stamp vessel

- Modular Process Skids

- Heavy Weld

- Custom Fabrication

- Large Industrial Fabrication

- Structural Fabrication

- Conventional and Custom Machining

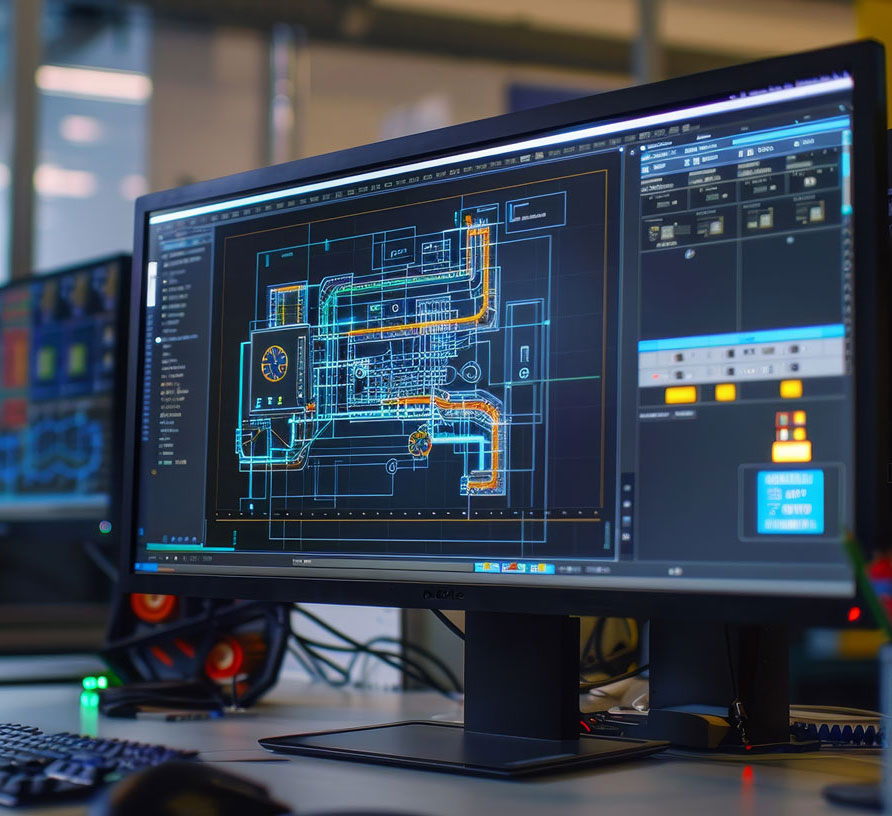

- Drafting & Design

- In-house Quality Control

HYDROGEN & WATER PROCESSING

Sawyer Fabrication is leading the way in developing innovative hydrogen production systems to upscale low-carbon hydrogen manufacturing, crucial for the energy sector's future. With global hydrogen demand expected to more than double by 2030, particularly in power, industrial, and transportation sectors, the company's expertise in water processing and special certifications is essential for growth.

Specializing in comprehensive hydrogen production systems, including power piping and vessels, Sawyer Fabrication is pivotal in carbon capture efforts and emission reduction. Our work in developing hydrogen and water processing infrastructure is key to advancing a sustainable and diversified energy landscape, preparing industries for a low-carbon future.

training and capabilities specific to hydrogen/oxygen equipment fabrication

- Certified personnel training for ASME B31.12 Hydrogen Power Piping

- Stainless Steel descaling (pickling) and augmented passivation per ASTME A380/A380M and ASTME A967/A967M

- Equipment and component cleaning for oxygen and hydrogen service per CGA-4.1

- Fully integrated Foreign Material Exclusion Program for the prevention of equipment and component contamination

HYDROGEN/OXYGEN Equipment fabrication for:

- Water Processing Plants

- Refineries

- Water Processing Plants

- Refineries

- Hydrogen Production Systems - Power Piping and Vessels

- Pure Oxygen - including Power Piping and Vessels

WATER CLARIFIERS

Sawyer Fabrication has rapidly scaled production of water processing components, including clarifiers, vessels, tanks, baffles, weirs, walkways and custom skids for municipal, industrial, and mining applications. Working from customer-supplied designs, our experienced team fabricates key structural and process equipment used in sedimentation, filtration, and sludge treatment. Whether it's a single stainless steel component or a full-scale clarifier system, we deliver precise, high-quality fabrication backed by decades of piping and construction experience.

Our in-house engineering team provides additional support for water processing projects, offering design assistance, drafting, and prototyping to meet specific application needs. As industries seek more sustainable water treatment systems, Sawyer Fabrication continues to be a trusted partner for high-performance, American-made solutions.

Sawyer Fabrication has built internal clarifier mechanisms for concrete basins in a wide range of diameters and configurations. The list below highlights a selection of recent and active projects.

- 1 - 80' Clarifier

- 1 - 50' Clarifier

- 1 - 65' Clarifier

- 2 - 110' Clarifiers

- 2 - 114' Clarifiers

- 2 - 114' Secondary Clarifiers

- 2 - 45' Secondary Clarifiers

- 2 - 50' Clarifiers

- 8 - 120" OD, 3 PH H2 Separators

- 1 - Set Effluent Troughs

- 2 - 24' Clarifiers

- 2 - 80' Clarifiers

- 2 - 45' Clarifiers

- 2 - 100' Clarifiers

- 2 - 80' Clarifiers

- 4 - 96' Clarifiers

- 2 - 120' Clarifiers

- 14 - 115' Clarifiers-SS

PRECISION & LARGE CAPACITY HONING

Sawyer Fabrication offers horizontal tube honing to produce smooth surface finishes and final sizing on cylindrical internal bores. We can hold tolerances to +.0001" in a variety of configurations and materials, including most alloy metals, stainless steel, and exotic alloys such as Inconel and Hastelloy. Our steel honing services produce higher accuracy from a smoother finish and geometric form of the bore.

WE SPECIALIZE IN HONING SERVICES THAT INCLUDE:

- Industrial Honing

- Hydraulic Cylinders

- Die Casting Shot Tubes

- Extruder Barrels

- Gas Flow Meter Tubes

- Fine Finish Bores

- Tight Tolerance Bores

- Thru Hole Bores

- Blind Bores

- Thin Wall Tube

- Diameter Range (ID): 2.5" - 21"

- Diameter Range (OD): 24" Max

- Part Length: 20" Max

- Stroke Speed Range: 5 - 90 ft./min.

- Surface Finish Range: 125 RMS - 8 RMS

ENGINEERING

Our engineering team provides comprehensive solutions for water processing, energy, and refining projects. With a dedicated in-house engineer, we support your project from concept through final implementation, ensuring quality, efficiency, and reliability at each stage. Our specialized services include:

- ASME pressure vessel design

- Custom piping and process systems

- Process skid design and fabrication

- Drafting, design, and prototyping of custom equipment

- Pipeline and process support engineering

Logistics

Sawyer Fabrication partners with trusted companies worldwide to ensure quick, cost-effective shipping. Our logistics experts handle everything from standard packaging to custom crates and large trailer-loaded projects, guaranteeing your fabrication arrives safely and on time—locally or globally.